Struggling with traditional fabric printing methods that can't keep up with today's demand for quality and customization? Digital fabric printing offers a modern solution. This technique brings precision, versatility, and the freedom to create stunning, detailed textile designs, setting a new standard in fabric printing.

What Is Digital Fabric Printing?

Digital fabric printing is a contemporary technique that involves using advanced digital technology to apply designs directly onto fabric. This method employs inkjet printers that are specially adapted for fabric printing. These printers meticulously apply tiny droplets of ink in various colors to create detailed, vibrant designs on the fabric.

Digital fabric printing is a contemporary technique that involves using advanced digital technology to apply designs directly onto fabric. This method employs inkjet printers that are specially adapted for fabric printing. These printers meticulously apply tiny droplets of ink in various colors to create detailed, vibrant designs on the fabric.

Unlike traditional fabric printing methods, which often involve screens or blocks to transfer designs, digital fabric printing allows for a high level of detail and an unlimited range of colors. This makes it particularly suitable for intricate patterns and photorealistic images.

This technique can be used on a wide variety of fabrics, including cotton, silk, and polyester, making it versatile for different applications. Digital fabric printing is also known for its precision and consistency, ensuring that each print is sharp and true to the original design.

In essence, digital fabric printing is a process where creativity meets technology, providing a modern solution for fabric design and production.

Advantages of Digital Printing:

Digital fabric printing is revolutionizing the textile industry with several key advantages, making it a valuable asset for businesses of all sizes, from small entrepreneurs to large corporations.

- Efficiency and Speed: Compared with traditional printing methods, the production time of digital printing is very short. This not only improves the efficiency of product production, allowing customers to receive goods earlier, but also allows enterprises to respond quickly to market demand and produce products that are more in line with trends.

- Good Cost Effectiveness: The cost of this printing method is not only very low for large orders, but also very economical for small orders. This flexibility is very beneficial for independent designers and individual sellers, who can encourage the creation of a greater variety of unique products.

- Superior Quality: Digital printing stands out for its high-quality output, producing vibrant colors and detailed designs. This precision meets the demands of artists and designers who seek to translate intricate patterns onto fabric flawlessly.

- Eco-Friendly Approach: In today's environmentally conscious market, digital printing's reduced waste, lower water usage, and energy efficiency make it an attractive option. This sustainability aligns with the values of many modern consumers and enhances a brand's eco-friendly image.

Digital printing is a very cost-effective way to print for small businesses and individual designers, who can create a variety of products to experiment in the market with less upfront capital investment. For those looking to enter the Print on Demand Business, partnering with a company like PrintKK can provide the necessary tools and support.

Types of Digital Printing on Fabric

Digital prInting on fabric has had a profound impact on the textile industry. This printing method meets the needs of diverse products with high quality printing technology and low economic cost. Understanding these types can help entrepreneurs, designers, and businesses select the most suitable technique for their projects.

Direct to Garment (DTG)

DTG is a popular method for printing directly onto cotton fabrics. DTG is an ideal choice for complex designs that include a variety of colors. It's ideal for intricate designs with multiple colors, such as custom skateboard, which require a high level of detail and color fidelity.

Custom Skateboard - Print on Demand Fulfillment - PrintKK

Custom Skateboard - Print on Demand Fulfillment - PrintKK

DTG is a popular method for printing directly onto cotton fabrics. It's ideal for intricate designs with multiple colors. It's ideal for intricate designs with multiple colors, such as custom skateboard, which require a high level of detail and color fidelity.

- Precision and Detail: DTG can produce colorful and bright prints. This kind of print is not only easy to leave a deep impression, but also more durable and does not fade easily.

- Flexibility in Design Changes: It allows for easy modification of designs, providing flexibility for short runs or custom orders.

Dye-Sublimation Printing

This method is best for polyester and other synthetic fabrics. This method requires heat to be applied to the fabric.

- Bright Color and Durable: Dye-sublimation produces bright, eye-catching prints that are durable and resistant to fading.

- Wide Application: It's suitable for a range of products, from apparel to flags and banners, offering versatility to businesses.

Pigment Printing

Pigment printing is gaining popularity for its simplicity and eco-friendliness. For those looking to create custom rugs, pigment printing offers an eco-friendly and versatile option, which can be explored with companies specializing in print on demand products.

- Broad Fabric Compatibility: This printing technology can be applied to a wide variety of fabrics such as cotton, silk or synthetic fibers, with a wide range of compatibility and application.

- Eco-Friendly: This method uses water-based inks and requires less water, aligning with sustainable practices.

Reactive Printing

Reactive printing is preferred for natural fibers like cotton and silk, known for its color vibrancy and wash durability.

- Rich, Vibrant Colors: It produces deep, bright colors that are long-lasting.

- Soft Hand Feel: The process leaves fabrics soft to the touch, ideal for high-quality apparel and home textiles.

Types of Fabric Printing Machine

In the dynamic world of fabric printing, understanding the types of printing machines is crucial for businesses looking to harness the power of digital technology. Each type of printer has unique advantages and can be well matched according to different industries.

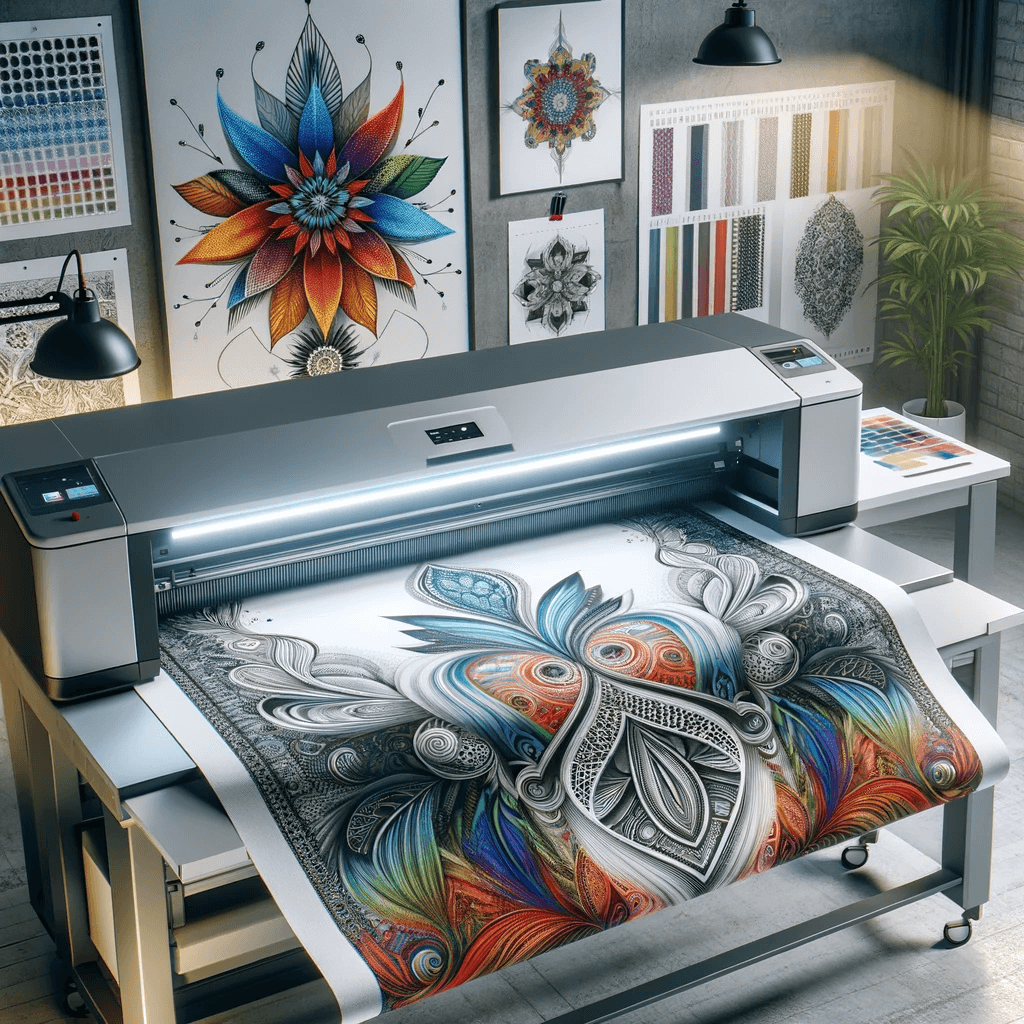

Inkjet Fabric Printers

Inkjet fabric printers are not only versatile, but also capable of printing very fine patterns. They are ideal for detailed designs and a wide color spectrum.

- High-Resolution Printing: These printers excel in producing crisp, detailed images, perfect for intricate designs.

- Versatility in Fabric Types: They can print on various fabrics, including cotton, silk, and synthetics, making them a flexible choice for diverse projects.

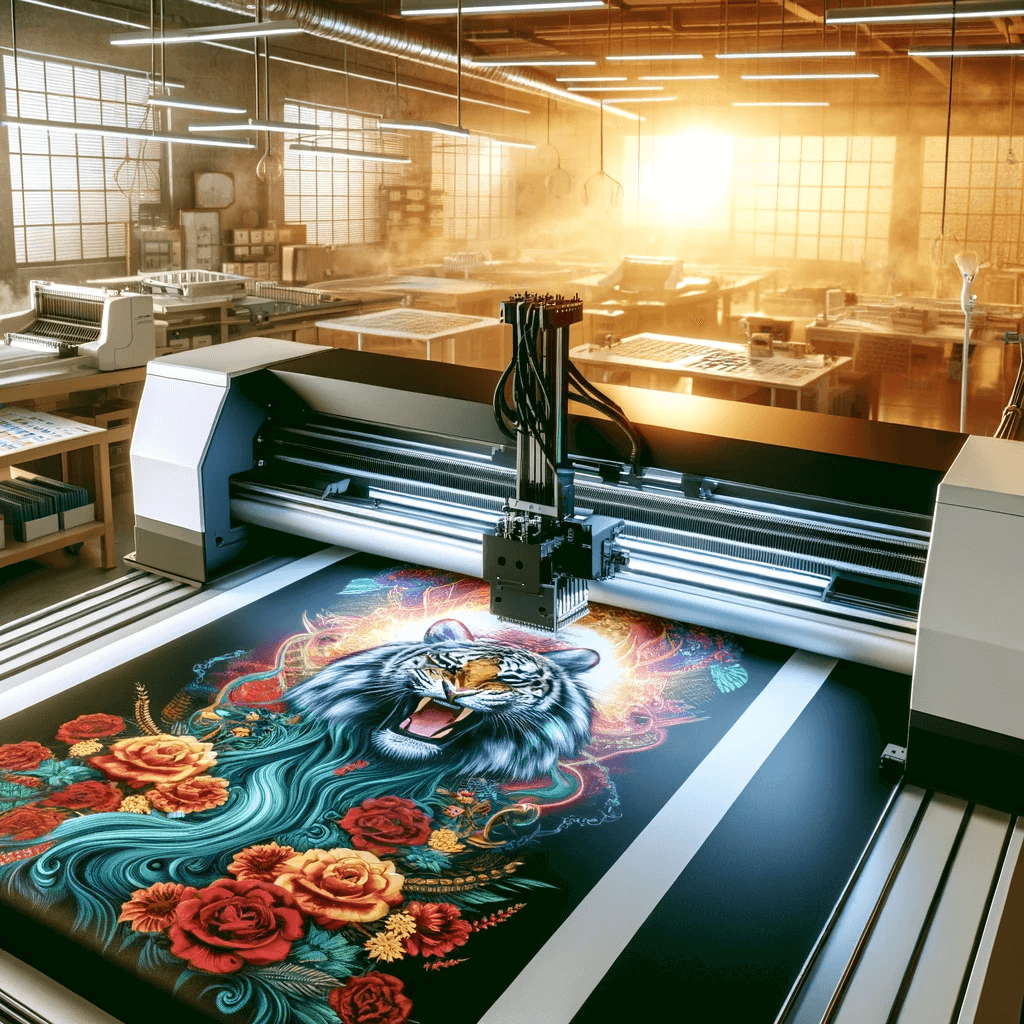

Sublimation Printers

Sublimation printers are the first choice for printing on polyester and various synthetic materials. The printer uses heat to transfer dye to the fabric to create brightly colored and durable patterns.

- Bright, Long-Lasting Colors: The prints are known for their color vibrancy and wash-fastness.

- Ideal for Sportswear and Banners: Their ability to produce stretch-resistant prints makes them perfect for sportswear, flags, and banners.

Direct to Garment (DTG) Printers:

DTG printers specialize in printing directly onto cotton-based fabrics. They are a popular choice for small-scale orders and custom designs.

- Excellent for Custom Orders: DTG is ideal for businesses that focus on personalized or small batch orders.

- User-Friendly: These printers are generally easier to operate, making them suitable for businesses with limited printing experience.

Rotary Screen Printers

Though not a digital method, rotary screen printers are still used for high-volume fabric printing. They are best for large orders where consistency is key.

- Efficient for Large Runs: They offer high-speed production for large volumes.

- Consistent Quality: Rotary screen printers provide uniform quality across extensive fabric rolls.

How Digital Printing on Fabric Works?

Understanding how digital printing on fabric works is essential for entrepreneurs, designers, and businesses looking to leverage this technology. Digital fabric printing is a process that combines precision, technology, and creativity to transform digital images into vibrant textile prints.

The Digital Design Process

You can use software such as Adobe Photoshop or Illustrator to start a digital design.

- Flexibility in Design: Digital printing allows for unlimited color choices and intricate details, offering designers complete creative freedom.

- Quick and Easy Modifications: Adjustments to the design can be made swiftly, ensuring the final product matches the intended vision.

Preparing the Fabric

Before printing, the fabric undergoes pre-treatment to ensure it can properly absorb the ink. This step is key to creating realistic and long-lasting prints.

- Enhanced Ink Absorption: Pre-treatment helps the fabric absorb the ink effectively, which is vital for sharp, clear prints.

- Suitability for Various Fabrics: Different fabrics may require specific pre-treatments, making the process versatile for various textile types.

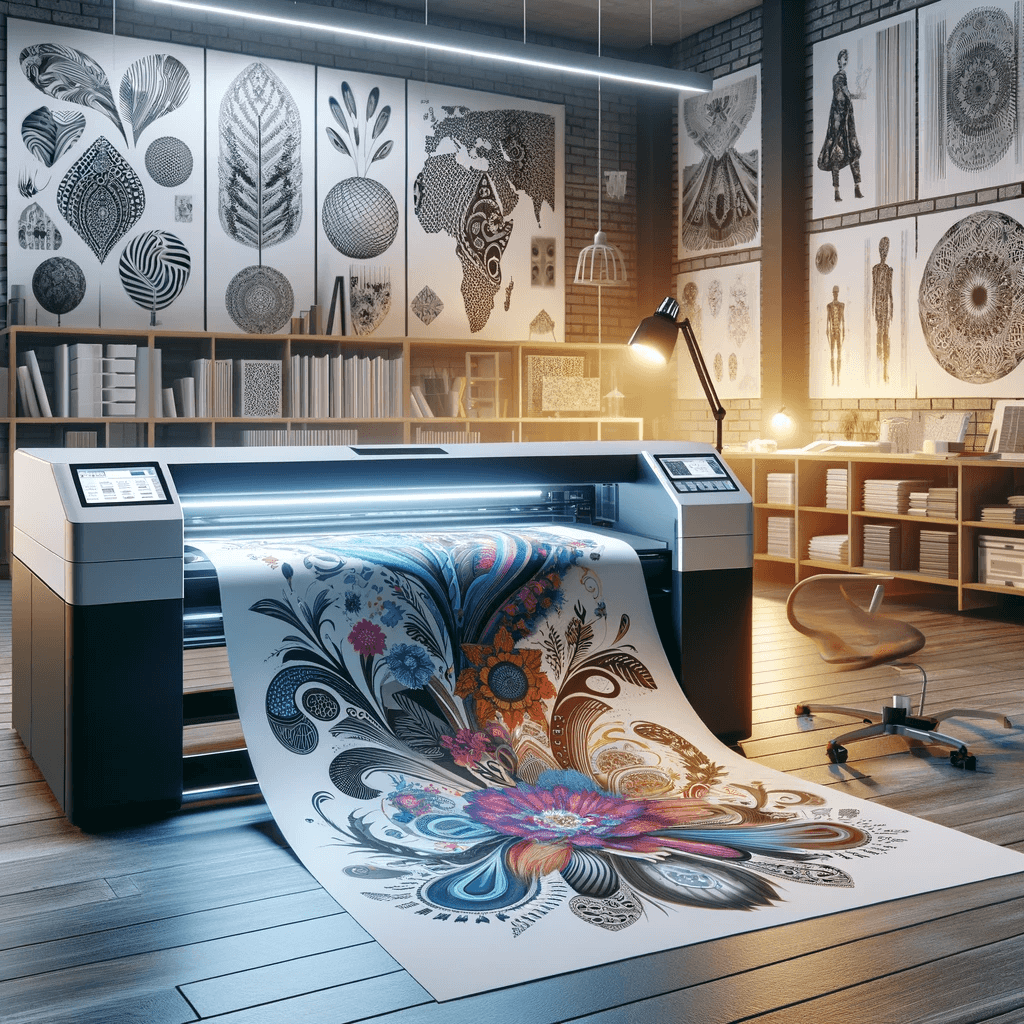

The Printing Process

Using specialized inkjet printers, the digital design is then printed directly onto the fabric. This printer can spray tiny drops of ink onto the fabric to perfectly restore your digital design.

- Inkjet Technology: The printers use CMYK or a wider color range to accurately produce the desired hues and shades.

- Detail Accuracy: This type of printing guarantees that no matter how complex and difficult the design is, it will be presented with the best detail and the most accurate colors.

Post-Printing Treatment

After printing, the fabric often undergoes post-treatment processes like steaming and washing. This step sets the ink and ensures the print's durability.

- Setting the Ink: Post-treatment processes like steaming help fix the ink onto the fabric, making the print resistant to fading and washing.

- Ensuring Print Longevity: Proper post-treatment guarantees that the fabric retains its vibrancy and detail over time.

The Process of Digital Fabric Printing

Digital fabric printing is a process that combines technology and creativity, transforming digital designs into beautiful printed fabrics. Let's walk through the key steps of this process, a journey from digital concept to tangible textile masterpiece.

Step 1: Design Creation

The process begins in the digital realm. Using graphic design software, artists and designers craft their unique visions. This stage is where creativity flourishes, with the freedom to experiment with a vast array of colors and intricate patterns.

- Creative Freedom: The digital platform allows for unlimited color use and detailed design creation.

- Flexibility: Quick and easy adjustments to the design can be made, offering adaptability to client needs or market trends.

Step 2: Preparing the Fabric

Once the design is ready, the fabric is pre-treated to ensure optimal print quality. This pre-treatment process is tailored to the fabric type, preparing it to receive the ink.

- Enhanced Ink Absorption: Pre-treatment improves the fabric's ability to absorb and hold the ink, crucial for vibrant and sharp prints.

- Suitable for Various Fabrics: Different fabrics may need specific pre-treatments, making digital printing versatile for different textile applications.

Step 3: The Printing Process

Here, the magic happens. Specialized inkjet printers transfer the digital design onto the fabric. These printers meticulously apply tiny droplets of ink, perfectly replicating the digital design.

- Precision Printing: Advanced printers ensure high-definition prints with exact color matching.

- Versatility in Design: This step can handle complex patterns and a full spectrum of colors, offering more design possibilities than traditional methods.

Step 4: Post-Processing

After printing, the fabric undergoes post-processing. This includes steaming and washing, which set the ink into the fabric and ensure durability.

- Longevity of Prints: Post-processing treatments solidify the ink's bond to the fabric, making the prints resistant to washing and fading.

- Quality Assurance: This final step ensures the print maintains its vibrancy and the fabric retains its quality over time.

Digital Printing vs Screen Printing

In the dynamic world of fabric printing, two prominent methods stand out: digital printing and screen printing. Both printing methods have unique advantages that allow them to adapt to the different needs of the on-demand printing industry.

Digital Printing: The Modern Approach

Digital printing is at the forefront of current printing technology. It engraves ink from the printer directly on the fabric.

- High efficiency: Digital printing is known for its high efficiency. Rapid production efficiency and timely turnover of goods can be perfectly adapted to small and medium-sized orders.

- Quality and Detail: This method excels in producing highly detailed prints with a wide color range. It's perfect for complex designs requiring high precision.

Screen Printing: The Traditional Technique

Screen printing, a method with a long history, uses screens, one for each color, to apply ink onto the fabric. It's a more manual process compared to digital printing.

- Friendly to for Large Orders: Since the number of products that need to be printed increases the cost, this printing method is more economical for large orders.

- Durability: Prints made with screen printing are known for their durability and vibrant colors, especially on dark fabrics.

Comparing the Two

When deciding between digital and screen printing, consider factors like order size, color complexity, and fabric type.

- Order Size and Turnaround: Digital printing is more suited for smaller, custom orders with a fast turnaround. Screen printing is suitable for large orders with plenty of time.

- Design Complexity: For products with high detail requirements and designs with more complex colors, digital printing is a good choice. Screen printing, while excellent for bolder, less complex designs, has limitations in color complexity.

Conclusion

Concluding our exploration of digital printing on fabric for 2024, we see it as a pivotal innovation in textile production, blending high-quality output with environmental consciousness. Ideal for various users, it offers versatility in design and scale.

This technology not only has a profound impact on the current textile printing industry, but also meets the diversified product needs of the current market, becoming an indispensable tool for enterprises and individual designers.

FAQs

What does digital print mean on fabric?

Digital printing on fabric uses inkjet technology to directly apply digital images onto textiles, known for its precision and versatility. It enables detailed, vibrant designs on various fabrics, popular for custom textile projects.

What are the pros and cons of digital printing on fabric?

Digital printing on fabric excels in producing high-quality, intricate designs and is eco-friendly, best for small to medium orders. However, it's less cost-effective for large volumes and may be limited by certain fabric types.

What is digital printing on apparel?

Digital printing on apparel employs inkjet technology for detailed, high-resolution images on clothing. Ideal for small or custom orders, it offers limitless colors, efficiency, and eco-friendliness, suitable for personalized apparel creation.

Global Shipping

Global Shipping