Want to start your own embroidery business, but not sure where to start? Don't worry, we'll walk you through the steps to successfully launch an embroidery business. Whether you want to do handmade embroidery at home or sell it through print-on-demand, we can help you find the best entry point.

In this article, we will not only dive into how to run an embroidery business, but also take you through the secrets of digital embroidery and how to deal with the challenges of small embroidery designs. You will learn how to improve your business skills, optimize processes, and maximize sales.

Are you ready to start this journey? Let's explore how to turn your embroidery ideas into a profitable business!

Why Start an Embroidery Business?

1. Growing Demand for Personalized Fashion

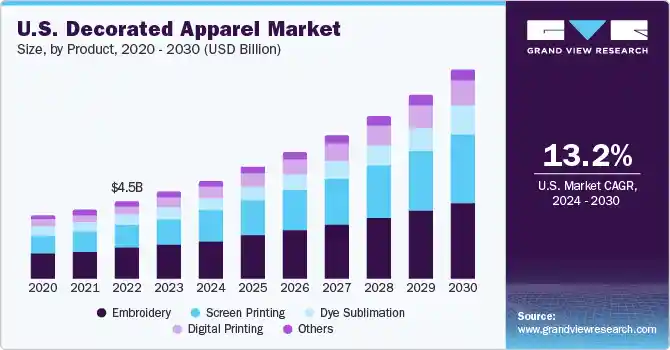

People want clothing and accessories that feel uniquely theirs. Embroidery stands out in the decorated apparel market because it adds texture and luxury that prints can't match. In 2023, this craft alone generated $11.7 billion in global revenue—making it the largest segment of the decorated apparel industry. By 2030, the market is expected to grow by 13.2% annually. This isn't a passing trend—it's a booming industry.

2. Low Startup Costs

You don't need a factory or fancy equipment to begin. Start small: sell custom patches, monogrammed towels, or branded hats. As demand grows, reinvest profits into better tools or hiring help.

3. Creative Freedom + Profit

Unlike generic T-shirt printing, embroidery lets you charge premium prices for intricate designs. A $5 plain tote can sell for $30+ with detailed stitching. Your creativity becomes your product—whether you're crafting vintage-inspired jackets or modern geometric patterns.

Bonus: Offer limited-edition designs to create urgency.

4. Flexibility to Work Anywhere

Run your business from home, a studio, or even a pop-up booth. Sell through:

This adaptability lets you test markets without long-term risks.

5. Tap into Multiple Markets

Embroidery isn't just for fashion. Expand into:

- Corporate merch (logo-stitched uniforms)

- Wedding decor (custom table linens)

- Home goods (embroidered pillowcases)

Diversifying keeps income steady and attracts varied clients.

With rising demand for personalized goods and low barriers to entry, embroidery offers a rare mix of artistic satisfaction and financial potential. Whether you're stitching by hand or using machines, your skills can turn thread into profit—one stitch at a time.

How to Start an Embroidery Business with Different Business Models?

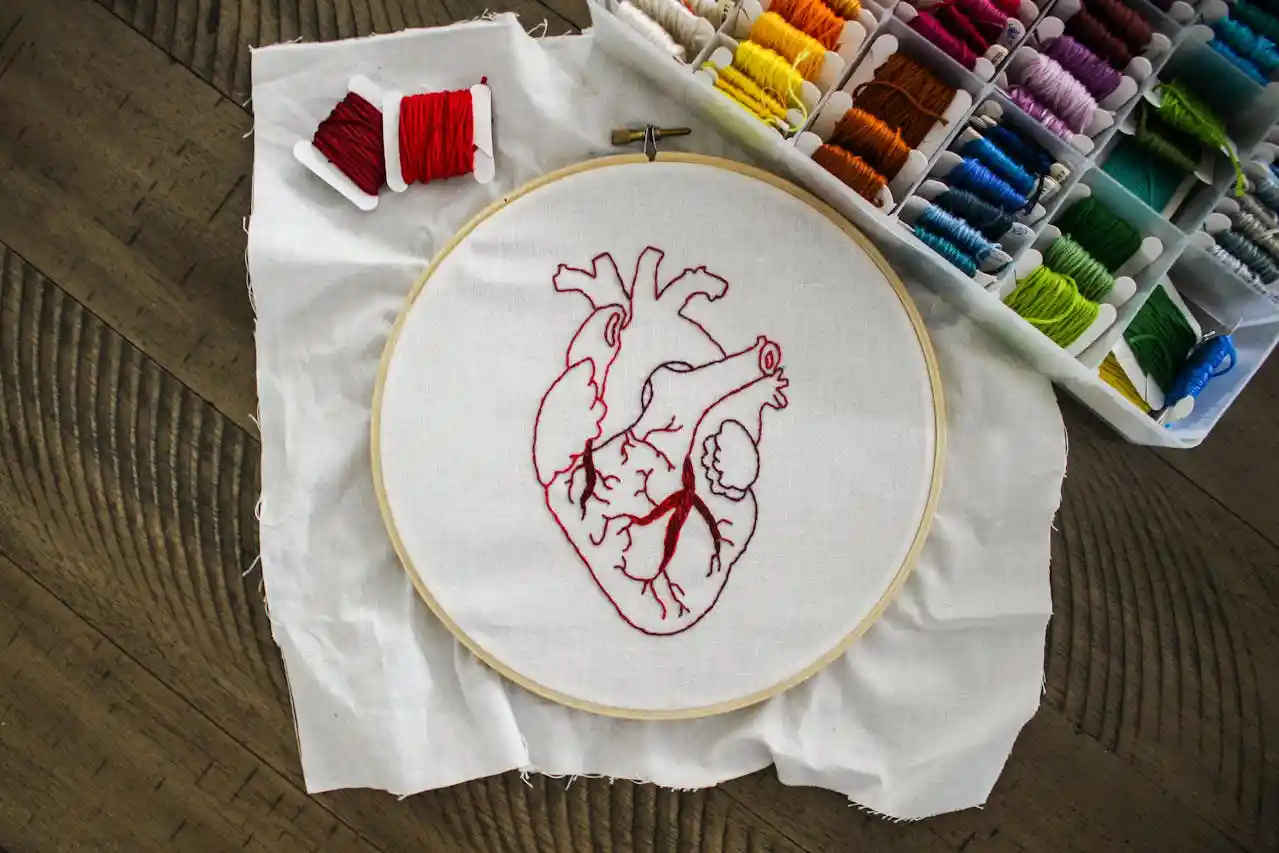

Crafting Luxury through Hand Embroidery

If you're passionate about intricate artistry and personalized touches, hand embroidery could be your niche. This model attracts customers willing to pay a premium for one-of-a-kind pieces—think wedding gowns, heirloom linens, or boutique fashion.

How to Start:

- Invest in high-quality hoops, needles, threads (silk or cotton), and fabrics.

- Practice creating intricate patterns, such as floral motifs or monograms.

- Build a portfolio with high-resolution photos of your work.

- Price your items 3-5 times higher than machine-made pieces to account for the labor and skill involved.

Challenges:

It can be time-consuming—one scarf, for example, may take over 20 hours. Focus on small batches or custom orders to avoid burnout.

Reflect:

Do you enjoy the slow, meditative nature of the craft? Can you market your creations as luxury art?

Home-Based Machine Embroidery

This model uses embroidery machines to produce designs more quickly. It's ideal for small businesses making hats, baby clothes, or branded merchandise locally.

Steps to Launch:

- Purchase a starter machine (around $2,000) and digitizing software (to convert images into stitch files).

- Source blank products such as T-shirts, totes, or caps from wholesalers.

- Offer customization by adding names, logos, or simple graphics.

Tips to Keep Costs Low:

- Use social media for free marketing (post behind-the-scenes reels).

- Partner with schools or small businesses for bulk orders.

- Pro tip: Keep your designs simple at first. Stick to bold, readable patterns that machines can handle easily.

Print On-Demand: Low-Risk Business with Zero Inventory

If you'd rather not handle physical products, consider partnering with print-on-demand (POD) services like PrintKK. The POD company handles printing, shipping, and returns when customers order your designs.

Why It Works:

- No upfront costs for inventory or equipment.

- Focus on design: Create trendy graphics (abstract shapes, witty quotes) for shirts, hoodies, or bags.

- Scale globally without the logistical challenges.

How to Stand Out:

- Research trending niches (pet-themed apparel, eco-friendly slogans).

- Use platforms that offer embroidery-specific services, not just standard prints.

Caution:

Profit margins can be thinner (around $15 per item). Make up for this by focusing on high-volume sales or premium designs.

Choosing Your Model: Key Questions

Before deciding which model suits you best, consider the following:

- Skill Level: Can you digitize designs yourself, or will you need to outsource?

- Budget: Hand embroidery requires fewer tools but limits output. Machines cost more but increase speed.

- Audience: Are you targeting local clients (like at craft fairs) or online shoppers (Etsy, Shopify)?

Mixing Models for Flexibility

Many businesses combine different models to diversify revenue streams. For example:

- Use hand embroidery for limited-edition collections.

- Run a POD store for passive income.

- Sell machine-embroidered accessories at pop-up markets.

This approach helps reduce reliance on one customer base.

How Much Does It Cost to Start an Embroidery Business?

Starting an embroidery business costs different amounts based on your setup. Let's break it down by three common models: handmade, home-based printing, and print-on-demand.

Handmade Embroidery Business

This is the cheapest way to start. You'll need basic tools like needles, thread ($2–$5 per spool), fabric ($10–$20 per yard), and hoops ($5–$15 each). A small single-needle machine costs $300–$800.

This works if you're doing custom orders or small batches. But production will be slow, so prices stay high to cover time.

Home-Based Machine Embroidery

Here's where costs jump. A multi-needle commercial-grade embroidery machine lets you switch thread colors automatically. Prices start around $20,000 for models handling 15 colors.

You'll also need digitizing software to turn designs into stitch patterns. Basic versions cost $2,000. Add thread, stabilizers, and maintenance—budget $25,000 total. This setup works if you want to sell bulk orders or partner with local businesses.

Print-on-Demand Embroidery

Zero upfront costs. POD platforms handle production—you upload designs, they print and ship. You pay per item (e.g., $15–$30 per embroidered hat) and set your retail price.

Lower profit margins since you don't control production. But use this to test designs or run a side hustle without risks.

Which model fits you?

- Handmade: Under $1,000, perfect for hobbyists

- Home-based: $15K–$25K, ideal for serious sellers

- Print-on-demand: $0 upfront, best for beginners

Why Are Small Embroidery Designs Tricky and How to Tackle Them?

Small embroidered designs can be tricky, particularly if you want detail. Worse, because designs are small, they give up a lot of their clarity. It gets difficult to show fine details simply because to know room.

Imagine trying to stitch a detailed picture of a car on a 3-inch square. It's tough. The embroidery will likely look nothing like a car. You might, instead, get a fuzzy outline, with detail entirely lost on you.

Why Is It So Difficult to Get Small Designs Right?

Limited Detail:

The smaller the design, the less detail it will be able to include. Frames under 5" encroach upon your ability to capture significant details. A tiny image can only have so many stitches in it, and those are difficult to make look realistic.

Stitching Issues:

More details means more stitches. However, too many stitches in a small area can cause crowding. This can form knots, and jagged, unclear designs.

Size vs Quality:

Small, detailed designs don't go well with embroidery machines because the size is too restrictive to allow the machine to make all the stitches it needs to make. Fine points tend to get smudged or understated.

How to Approach Tiny Embroidery Pieces

Increase the Size:

To maintain details crisps, a good idea is to slightly increase the size of your design. Simply making it slightly bigger can help with clarity.

Keep the Design Simple:

If you really want to keep things condensed, you might want to have a simpler design. Look for wider, bolder features, such as outlines or good shapes to try to create, rather than intricate details.

Use a Skilled Digitizer:

There are times when you should actually surrender to the hands of a digitizer that can perfect your design with embroidery in mind. A good digitizer knows how to simplify while preserving important details.

Small embroidery designs are tricky, but knowing these challenges will help you produce better products in a more professional way.

Digitizing Is the Key to Success in Your Embroidery Business

When starting an embroidery business, one of the most important skills you will need is digitizing. Digitizing is the process of converting a design or logo into a file that can be read by embroidery machines. Without a properly digitized file, your machine won't be able to produce high-quality results.

1. Why is Digitizing So Important?

Digitizing can make or break your embroidery. Without it, you cannot produce the design you want on fabric. It's not just about picking a design and stitching it. Digitizing requires precision. The right stitch types, densities, and directions must be chosen to ensure the design looks good on fabric.

- Inaccurate digitizing leads to messy, low-quality embroidery.

- A poorly digitized file can result in wasted time, materials, and money.

2. Outsourcing Digitizing

You don't have to learn digitizing immediately. In the beginning, outsourcing digitizing is a great option. Many professionals can digitize your design for a reasonable price.

- You can expect to pay about $15-$25 for each logo to be digitized.

- Once done, you own the embroidery file forever.

- This means you won't have to pay for digitizing the same design again.

Outsourcing helps you save time and focus on other aspects of your business, such as production and marketing.

3. Learning to Digitize

Although outsourcing works for now, eventually, you might want to learn digitizing yourself. Keep in mind, digitizing is not an easy skill to master. It can take years of practice to get it right.

- Digitizing is a time-consuming process that requires a lot of patience.

- The more intricate the design, the more difficult it becomes to convert it into an embroidery file.

However, once you become skilled in digitizing, it gives you more control over your designs and can save costs in the long run.

Expert Tips

Starting an embroidery business can be exciting and profitable. With the right approach, you can turn your creative passion into a successful venture.

Never underestimate the power of digitizing. No matter if you outsource or learn it for yourself, having the correct digitizing is important for a good result.

Stay focused, be patient, and continue improving. Over time, your business will grow and thrive. The path may be challenging, but with dedication, you can achieve success in the embroidery industry.

Global Shipping

Global Shipping