Embarking on the ever-evolving journey of digital printing, a realm where innovation meets practicality, this exploration delves deep into the essence of digital prints. A technology that has not just evolved but revolutionized the printing industry, digital printing stands as a beacon for entrepreneurs, designers, and businesses alike. From the intricate process of creation to its diverse applications, this guide unravels the myriad ways digital printing can transform your projects, turning abstract ideas into vivid, tangible realities. Join us as we navigate this progressive landscape, unveiling the transformative power of digital prints in today's fast-paced world.

What Is Digital Printing?

Digital printing stands as a modern printing method where images are directly printed onto various materials from a digital file. This technique contrasts with traditional methods like offset printing, which uses plates to transfer images onto paper. Digital printing shines in its ability to handle small print runs and personalized printing with ease. It's particularly advantageous for entrepreneurs and small business owners who require flexibility and quick turnaround times for their custom designs.

For designers, artists, and brands, digital printing opens up a world of possibilities. This method allows for high-quality prints with vibrant colors and intricate details, making it ideal for creating everything from custom apparel and accessories to marketing materials and home decor. Moreover, digital printing is cost-effective for short runs, making it a go-to choice for dropshippers and businesses testing new designs in the market. Its efficiency and precision cater to the dynamic needs of today's fast-paced, design-driven industries.

How Does Digital Printing Work?

Shifting focus to the operational side, understanding how digital printing functions is key for entrepreneurs and designers looking to leverage this technology. Essentially, digital printing involves transferring a digital image directly onto a printing surface. Unlike traditional methods that use printing plates, digital printing streamlines the process, making it ideal for small-scale and custom print jobs.

The process starts with a digital file, such as a PDF or JPEG, which is sent to the printer. Modern digital printers use either toner, akin to that in laser printers, or liquid ink. This adaptability allows for printing on a wide range of materials, including paper, canvas, fabric, synthetics, and cardstock. The ink or toner forms a thin layer on the surface and is then fused onto it, often through heat. This technique excels in producing prints with detailed, vibrant designs. For those in the print-on-demand industry, this means the ability to quickly produce high-quality, customized products that meet the dynamic needs of their market.

Digital Printing Advantages and Disadvantages

1. Advantages of Digital Printing

Digital printing brings a host of advantages, particularly beneficial for entrepreneurs, designers, and businesses in the print-on-demand sector. Key benefits include:

- Rapid Turnaround: Digital printing streamlines the production process, enabling faster completion of orders. This speed is a boon for businesses needing quick deliveries.

- Cost-Effectiveness for Small Batches: Ideal for small-scale orders, digital printing eliminates the need for plates and setup costs, making it more economical for limited runs.

- High-Quality Output: It produces sharp, high-resolution images with vibrant colors, essential for detailed designs and professional-looking products.

- Customization Ease: Digital printing allows for easy customization, supporting businesses that offer personalized products to their customers.

- Eco-Friendly Approach: With less ink usage and waste production, digital printing aligns with eco-conscious business practices, appealing to environmentally aware consumers.

These advantages make digital printing a versatile and attractive option for various business models, from independent artists to large-scale organizations.

2. Disadvantages of Digital Printing

While digital printing offers numerous benefits, it's important to consider its disadvantages, especially for businesses evaluating their printing options. Some of the drawbacks include:

- Higher Cost for Large Orders: For bulk printing, digital printing can be less cost-effective compared to traditional methods like offset printing.

- Material Limitations: Digital printers may not support all types of materials and textures, which could restrict design possibilities.

- Durability Concerns: Prints produced digitally might not always match the durability of those created through traditional methods, potentially fading faster under certain conditions.

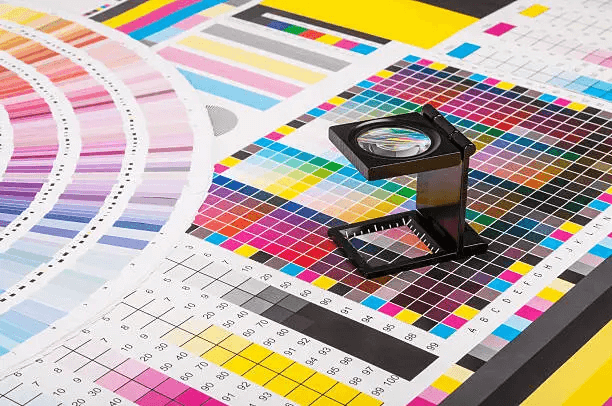

- Color Matching Challenges: Achieving exact color matches can be more difficult with digital printing, which might be a concern for brand-specific color requirements.

Understanding these limitations is crucial for businesses to make informed decisions that align with their specific needs and project goals.

Digital Printing vs. Offset Printing

Digital printing and offset printing are two distinct methods in the world of print production, each with its unique strengths and applications. Understanding the differences between these two can help businesses, designers, and entrepreneurs make informed decisions for their printing needs.

Digital Printing:

- Flexibility and Customization: Ideal for small to medium-sized runs, digital printing excels in producing customized, variable data prints like personalized marketing materials.

- Quick Turnaround: With no need for plate setup, digital printing offers faster production times, crucial for tight deadlines.

- Cost-Effective for Small Runs: It reduces costs for smaller quantities as it doesn't require the setup involved in offset printing.

- Quality and Color: Digital printing provides high-quality prints with excellent color accuracy, suitable for detailed graphics and vibrant images.

Offset Printing:

- Cost-Effective for Large Volumes: For large print runs, offset printing is more economical. The initial setup costs are offset by the lower per-unit cost for high volumes.

- Material Versatility: Offset printing can handle a wider range of paper types and thicknesses, offering more options for print projects.

- Color Precision: It allows for precise color control and consistency, which is vital for brand-specific color requirements.

- High-Quality Output: Offset printing produces sharp, clean images and type, ideal for professional-grade printing.

Each method has its place in the print industry. Digital printing is often the go-to for modern, fast-paced print demands, especially in the print-on-demand sector. In contrast, offset printing remains the preferred choice for traditional, high-volume print jobs where cost, material diversity, and color precision are paramount.

Types of Digital Printing

A variety of techniques fall under the umbrella of digital printing, each tailored to meet specific needs and applications. This versatility makes digital printing a popular choice among entrepreneurs, designers, and businesses. Here are some key types:

- Inkjet Printing: This method is renowned for its flexibility. Inkjet printers eject fine droplets of ink onto the print surface, making them ideal for detailed and high-resolution images.

- Laser Printing: Favored for its precision and speed, laser printing employs toner and heat for image transfer onto paper, suitable for text-heavy documents and large-volume jobs.

- Dye-Sublimation Printing: Best for fabrics and rigid materials, dye-sublimation stands out for vibrant colors and durability, commonly used for apparel and promotional items.

- Direct to Garment (DTG): Tailored for textile printing, DTG involves printing directly onto fabric, offering a soft feel and intricate designs, perfect for custom apparel.

- UV Printing: This type utilizes ultraviolet lights to dry or cure ink as it's printed. UV printing is effective on various materials, including plastics, and is known for its weather-resistant qualities.

Each type of digital printing method brings unique advantages, serving the diverse requirements of various industries. From producing high-quality art to swiftly creating marketing materials, the array of digital printing techniques ensures a fitting solution for almost every printing need.

What Is Digital Prints Used For

Digital prints are a cornerstone of modern creativity and commerce, blending artistry with technology. This process involves creating artwork or images using digital methods, then printing them onto various physical surfaces. Unlike traditional printing, digital prints offer unparalleled precision, vibrant color accuracy, and the ability to easily modify designs. This flexibility makes digital prints ideal for custom, on-demand products.

Entrepreneurs and artists frequently use digital prints for a myriad of applications. From personalized home decor to custom apparel, the possibilities are vast. Businesses utilize digital prints for promotional materials, corporate branding, and even packaging, making it an indispensable tool in today's market. The ease of reproducing high-quality images ensures that every print, from the first to the thousandth, maintains consistent quality.

Examples of Digital Printing

The versatility of digital prints extends across various industries, revolutionizing the way businesses, artists, and entrepreneurs approach printing. Here are some examples of the primary applications:

- Custom Apparel: Ideal for brands and designers, digital printing enables the creation of personalized clothing items like t-shirts and hats.

- Marketing Materials: Quick turnaround and high quality make digital prints a popular choice for flyers, brochures, and banners in business promotions.

- Home Decor: Artists and interior designers often opt for digital prints to produce unique wall art, outdoor cushions, and curtains.

- Personalized Gifts: The customization capability of digital printing is perfect for one-of-a-kind gifts such as photo books, mugs, and phone cases.

- Packaging and Labels: Both small businesses and larger corporations benefit from the flexibility and customization offered by digital printing for packaging and labels.

This wide range of uses demonstrates the adaptability of digital prints, making them a preferred solution in various sectors for both creative and practical applications.

Conclusion

To sum up, digital prints have emerged as a pivotal element in the modern printing landscape, offering unparalleled versatility and efficiency. From custom apparel and marketing materials to unique home decor and personalized gifts, digital printing has opened new avenues for creativity and business opportunities. Its ability to produce high-quality, customized products quickly and cost-effectively makes it an ideal choice for a wide range of applications. Whether for small businesses, individual artists, or large corporations, digital printing offers solutions that cater to diverse needs and preferences.

Moreover, the adaptability of digital prints across various sectors underscores their significance in both creative and practical domains. As technology continues to evolve, digital printing stands at the forefront, continually expanding its capabilities and applications. This adaptability ensures that digital prints remain a preferred solution for various industries, enabling businesses and creators to keep pace with evolving market trends and consumer demands. The future of digital printing looks bright, promising continued innovation and growth in the years to come.

FAQs

How long does digital printing last?

Digital prints are known for their durability, typically lasting for several years. The lifespan can vary based on factors like ink quality, material used, and exposure to elements, with prints on high-quality materials and proper care lasting upwards of 10 years or more.

Is digital print good quality?

Absolutely! Digital printing offers excellent quality, producing sharp, high-resolution images with vibrant colors. Advances in technology have greatly enhanced its precision, making it ideal for detailed designs and ensuring consistency across prints, which is crucial for professional and artistic applications.

Why is digital printing more expensive?

Digital printing can be more expensive due to its advanced technology and the high-quality materials used. It offers greater flexibility for small runs and customization, which involves additional costs. However, this cost is often offset by the value of precise, high-resolution, and customized prints.

What's the difference between screen printing and digital printing?

Screen printing involves transferring ink through a mesh screen onto the material, best for large batches and fewer colors. Digital printing, on the other hand, directly prints the digital image onto the material, ideal for detailed, multi-colored designs and smaller quantities.

What tools are used for digital printing?

Digital printing primarily uses inkjet or laser printers. Inkjet printers spray ink onto the material, while laser printers use toner. Other essential tools include design software for creating digital images and color management systems to ensure accuracy and consistency in prints.

Global Shipping

Global Shipping

Made in USA

Made in USA