Unlock the secrets to selecting the perfect shirt printing method for your needs. Whether you're starting a new clothing line or crafting unique gifts, this guide helps you navigate the various printing techniques to ensure quality and satisfaction. Explore your options and make informed decisions to elevate your designs.

What Are the Common Types of Shirt Prints?

Foil Printing

This process involves adding a metallic foil to the printing process. A layer of adhesive is screen printed onto the shirt in the desired design, then a foil sheet is applied and removed after heat pressing. This leaves the foil adhered to the adhesive-printed areas only, creating a shiny, eye-catching effect. Foil printing is popular for fashion-focused designs or any project requiring a touch of shine.

Screen Printing

Screen printing is revered for its versatility and cost-effectiveness. This technique involves creating a stencil (or screen) and using it to apply layers of ink on the printing surface. Each color is applied using a different stencil, one at a time, to achieve the final look. This method allows for vibrant colors even on darker shirts, making it ideal for bold and graphic designs that require a high level of vibrancy and durability.

Water-Based Printing

This method uses water-based inks that are absorbed directly into the shirt's fibers, rather than sitting on top of the fabric like plastisol inks. The result is a much softer feel, ideal for designs that cover a large area of the shirt and need to maintain breathability.

This type of printing is perfect for achieving a vintage look or when a soft, subtle print is desired. It's also a popular choice for brands committed to environmental sustainability, as the inks are non-toxic and use fewer chemicals compared to traditional plastisol inks.

Direct to Garment (DTG)

DTG printing is akin to printing on paper, but instead, it's done on fabric. This method sprays the ink onto the garment, allowing for high detail and a wide range of colors. It's perfect for small orders and intricate designs with shading and gradients. The ink used is generally water-based, absorbing into the fabric, which results in a softer feel on the shirts. DTG is highly effective for custom one-offs or limited runs where detail and color fidelity are critical.

Dye Sublimation

Unlike traditional printing methods that lay ink on top of the textile, sublimation uses heat-sensitive inks that turn into gas when heated. This process embeds the ink into the fabric, which makes the print almost undetectable to touch and extremely durable.

Dye sublimation is perfect for polyester materials, commonly used for creating custom jerseys, flags, and banners that require high levels of detail and an all-over print capability.

Vinyl Graphics

Using a special soft clothing vinyl, this method involves cutting out designs and heat-pressing them onto the t shirt. Vinyl graphics are extremely durable and are perfect for designs that require sharp edges and vivid colors. This technique is commonly used for slogans, logos, and graphics that need to stand out and last long.

Plastisol Transfers

This technique involves screen printing the design onto a special transfer paper using plastisol ink, which is then transferred to the fabric through heat and pressure. The major advantage of plastisol transfers is their ability to produce vibrant, crisp, and full-color images that are as durable and stretchable as direct screen prints.

It can be applied to a wide range of fabrics, although they are best suited for thicker materials where the heavier ink deposit is less likely to alter the fabric's feel.

Discharge Printing

Discharge printing involves removing dye from the fabric, particularly dark textiles, and then coloring the bleached areas. This technique results in incredibly soft prints and is highly effective for creating vintage or distressed looks on cotton fabrics where the natural cotton color contrasts well with the dyed fabric..jpg)

What Types of Custom T-Shirt Prints Are Commonly Used?

Direct to Garment (DTG):

Direct to Garment printing shines when it comes to precision and detail, leveraging the latest in printing technology. Unlike traditional methods, DTG works much like a desktop printer, applying specialty water-based inks directly onto the fabric and allowing for almost photographic detail with a vast spectrum of colors.

This method is particularly suitable for custom or small batch orders where each piece may have a unique design. DTG is also noted for its soft feel, as the ink integrates directly with the fabric without creating additional texture on the surface.

Screen Printing:

Screen printing remains a top choice for large-volume orders due to its efficiency and economic benefits in bulk production. The process begins with creating unique stencils for each color in a design, which are then used to apply ink to the fabric through a mesh screen.

The durability of screen-printed shirts is exceptional, making them a staple for promotional items and merchandise that need long-lasting quality. Moreover, the vibrancy of the colors achieved through this method is unmatched, especially on darker fabrics. The setup process, although time-intensive, results in a print that can withstand countless washes without fading.

Heat Transfer:

Heat transfer printing offers a flexible and fast solution for customized T-shirt designs. This method involves printing a design onto special paper and then transferring that image onto the shirt using heat and pressure. It's ideal for on-the-spot printing at events or for producing vividly colored designs quickly and at a low cost.

Heat transfer is versatile enough to work on a variety of fabric types and colors, including synthetics, making it a popular choice for decorative and photographic prints that require clarity and fine color gradients.

Sublimation Printing:

Sublimation stands out for its ability to produce seamless, edge-to-edge designs with incredible clarity and color depth. This technique involves turning solid dye into gas without passing through a liquid stage, embedding the dye into the fabric. This results in durable, undistorted, and fade-resistant images that are fully integrated into the fabric rather than sitting on top of it.

Sublimation is exclusively effective on light-colored, synthetic materials like polyester, making it perfect for sportswear and other applications where durability and performance are crucial..jpg)

How to Choose the Type of Shirt Print That Best Suits Your Needs?

1.Define Your Design Requirements

Start by clearly defining what your design entails. Consider the number of colors involved, the level of detail in the design, and the visual impact you aim to achieve. High-detail, multi-color designs might benefit from Direct-to-Garment (DTG) printing, which can seamlessly handle intricate and colorful graphics.

If your design is simpler, or you require a large volume, screen printing might be more cost-effective. It offers vibrant, durable results but is best for designs with fewer colors. Evaluate the nature of the artwork and the expected outcome to choose the most suitable method.

2.Consider Your Production Volume

Your order size plays a critical role in selecting a printing method. Screen printing, for example, has higher initial setup costs due to the need to create screens for each color. Therefore, it becomes cost-effective only at higher volumes. For smaller batches or limited edition runs, DTG is a better choice as it requires no setup and can efficiently handle small orders. Assessing your production volume will help you balance cost with efficiency.

3.Evaluate Fabric and Print Durability Needs

Different printing methods interact with fabrics in various ways, which can affect the longevity and wearability of the print. Consider the type of fabric you'll be using—some methods, like dye sublimation, work best on polyester, while others, like DTG, are more versatile but may fade faster on certain materials. Additionally, think about how the shirts will be used; if they need to withstand heavy wear and frequent washing, choose a method known for durability like screen printing. (1).jpg)

A Few Things to Consider When Making the Print of Your Shirt

Design Compatibility with Printing Method

Assess the compatibility of your design with the printing method you choose. Each technique, from screen printing to DTG (Direct-to-Garment), has its strengths and limitations. For instance, screen printing delivers vibrant colors and high durability, making it ideal for bold graphics on large batches. Conversely, DTG allows for more detailed designs and color gradients, suitable for complex or photographic images on smaller orders.

Material Considerations

The type of fabric you select also plays a pivotal role. Certain materials, like cotton, are well-suited for most printing methods, offering durability and comfort. However, synthetic fabrics like polyester might require specific methods such as dye sublimation to ensure the print adheres well and remains vibrant. Consider the end use of the shirts to choose the most appropriate fabric that aligns with the functionality and comfort your customers expect.

Cost-Effectiveness and Sustainability

Factor in the cost-effectiveness of the printing method and its environmental impact. Methods like water-based screen printing offer an eco-friendlier alternative, using inks that are less harmful to the environment. Analyzing the cost per unit based on your order size can help determine the most economical option without compromising quality. Additionally, consider the longevity of the print, as more durable prints may appeal more to customers looking for quality and sustainability..jpg)

The Best Way To Print T-Shirts At Home

Engaging in print-on-demand (POD) t-shirt printing at home has become a viable business strategy for many, thanks to its low overhead and ease of setup. Here's a breakdown of the process to help you get started:

Step 1: Choosing the Right Printer and Materials

The first step in setting up a home-based POD t-shirt business is selecting the right printer. Direct-to-garment (DTG) printers are ideal for high-quality, colorful designs and work directly on the fabric, making them perfect for detailed graphics. You'll also need high-quality t-shirt blanks; choose materials that reflect your brand's values and customer expectations.

Step 2: Design Software and Marketplace

Utilize robust graphic design software that can handle intricate designs and allows you to preview how these will look on different t-shirt colors and styles. Once your designs are ready, platforms like Shopify or PrintKK can be used to host your online store, or you can integrate with an existing website using POD services like PrintKK or Printful that automate the printing and shipping process.

Step 3: Marketing Your Brand

Effective marketing is crucial. Use social media platforms to showcase your designs and share behind-the-scenes content about your creation process. Engage with your audience through promotional offers, customer testimonials, and by highlighting the unique aspects of your designs. SEO-rich blog posts about your design process or fashion tips can also drive traffic to your site.

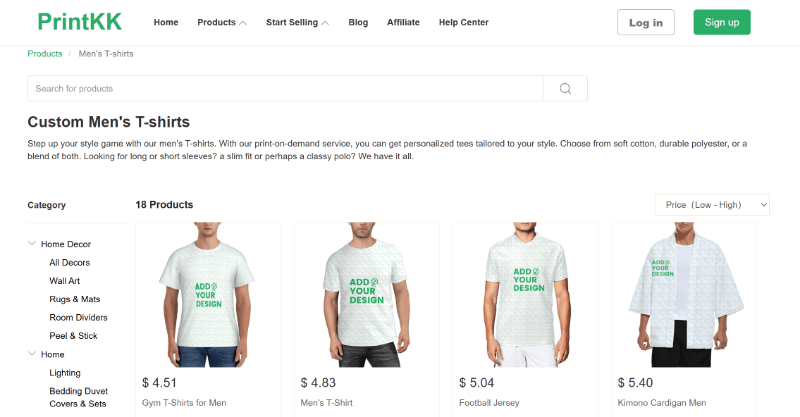

Make High-Quality Shirt Prints with PrintKK

Creating a custom shirt print with PrintKK is straightforward, ensuring that even those new to print-on-demand can produce high-quality apparel. If you're not a designer, PrintKK offers templates and design tools that make it easy to create professional-looking designs. Ensure your designs are high resolution to avoid any loss of quality during the printing process.

PrintKK supports various file formats, allowing you to upload your design directly through their platform. Pay attention to the dimensions and color specifications to ensure your final print looks exactly as intended.

Choose the type of shirt and printing method that best suits your design. PrintKK offers a variety of shirt styles and materials, from classic cotton tees to performance blends. Depending on your design's complexity and color requirements, choose from several printing techniques available. PrintKK's team can assist you in deciding the best method based on your design and order volume.

Conclusion

In concluding our exploration of shirt printing techniques, it's crucial to recognize that the best method depends on your specific needs. Whether you're an entrepreneur looking to start a new apparel brand or a designer aiming to showcase unique graphics, the choice of printing technique can significantly influence the final outcome.

Always align your choice with your business goals and customer expectations to ensure satisfaction and quality. By carefully selecting the appropriate printing method, you can optimize both the quality and impact of your printed shirts, making them not just apparel, but a statement.

FAQs

Which type of t-shirt print sells the best?

Screen printing remains the top-selling t-shirt print method. Ideal for bulk production, it offers durability and a professional finish.

Which shirt print is the most cost-effective to produce?

Heat transfer printing emerges as the most cost-effective method for producing shirt prints, especially for small batches and custom designs.

Which shirt print lasts the longest?

Screen printing holds the title for the longest-lasting shirt print method, renowned for its durability and color retention even after multiple washes.

Global Shipping

Global Shipping